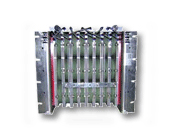

Ceramic Resistor Assemblies

Ceramic Carbon Resistors can be offered separately, in matched sets with respect to Resistance Value, or pre-assembled for ease of installation. Resistor Discs can also be supplied in stacks, marked and numbered for optimum flatness and parallelism.

It is recommended that HVR carry out any assembly work since using our specialised jigs, we will ensure that Resistor Discs are aligned correctly and that the appropriate mounting force is applied. This is important not only for mechanical reliability, but in minimising the risk of electrical activity between successive resistor discs and the disc / terminal interface.

Wherever possible, a Resistor Assembly will be designed using standard components, thus enabling us to offer the most cost effective solution.

Standard Assembly Components

- Glass Fibre Pultruded Tie Rod onto which the Resistor Discs are mounted

- Aluminium Hexagon End Stops, pinned at either end

- Schnorr Disc Springs which provide the compressive mounting force (≥ 350 kg)

- Insulated Stand Offs (Glastic) for ease of installation

- Cranked Aluminium Terminals for Electrical Connection

Alternative Design options

In some applications, it may be necessary to include other components so that the Resistor Assembly will meet Electrical, Thermal and Mechanical Design Specifications. These may include:

- Using a High Tensile Steel Bolt and Insulating Bushes for UL94 V-0 Regulations

- Aluminium Ferrule / Spacers for increased Average Power Rating

- Aluminium Cooling Fins for increased Average Power Rating

- Water Cooled Plates for increased Average Power Rating. If required, Cooling Plates can be electrically isolated from the Resistor Discs.

- High Current Terminals for Optimum Current Distribution

- High Current Terminal / Spacers for Improved Average Power Rating

- Customised Components where required e.g. Tinned Copper Terminals

- Customer Specific Components e.g. Thermal Switches